High-Strength 400D Polypropylene Rope – Factory Direct for Craft, Outdoor & Bag Making

Imagine this: a weekend crafter threading vibrant strands through a crochet hook, transforming a simple rope into a bohemian wall hanging. A backpacker in the Rockies securing a tarp between pine trees as dusk settles. A designer stitching bold new tote bags with reinforced handles that won’t fray after months of use. What ties these scenes together? The unassuming yet extraordinary 400D polypropylene rope—a material quietly revolutionizing how we create, explore, and carry.

When Strength Meets Creativity: How One Rope Transforms Worlds

It looks like any other cord—slender, smooth, coiled neatly on a spool. But don’t let its simplicity fool you. This rope is showing up everywhere: in artisan markets, hiking trails, urban workshops, and backyard gardens. From handcrafted home décor to life-saving outdoor setups, it’s proving that durability and design aren’t mutually exclusive. Whether you're knotting a dreamcatcher or anchoring a shelter in a storm, this isn’t just string—it’s a silent partner in every success.

Decoding 400D: More Than a Number—It’s a Promise of Performance

You’ve seen “400D” stamped on gear labels and product tags. But what does it mean? In textile science, “D” stands for denier—a unit measuring fiber thickness. Specifically, 400D means each strand weighs 400 grams per 9,000 meters. That might sound technical, but the real-world impact is clear: optimal balance between strength and flexibility. Too thick, and the rope becomes stiff; too thin, and it risks snapping under tension. At 400D, polypropylene delivers rugged resilience without sacrificing workability.

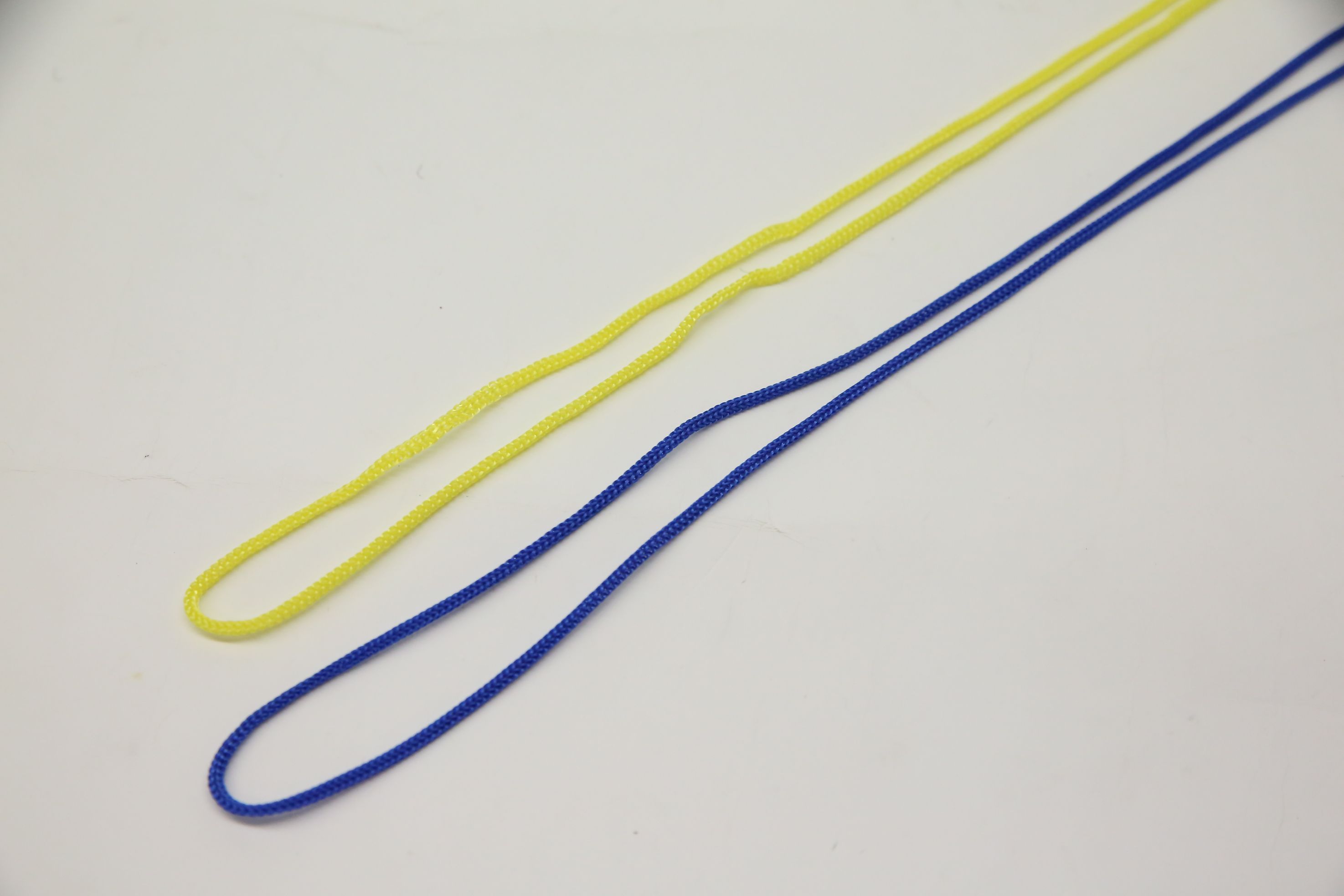

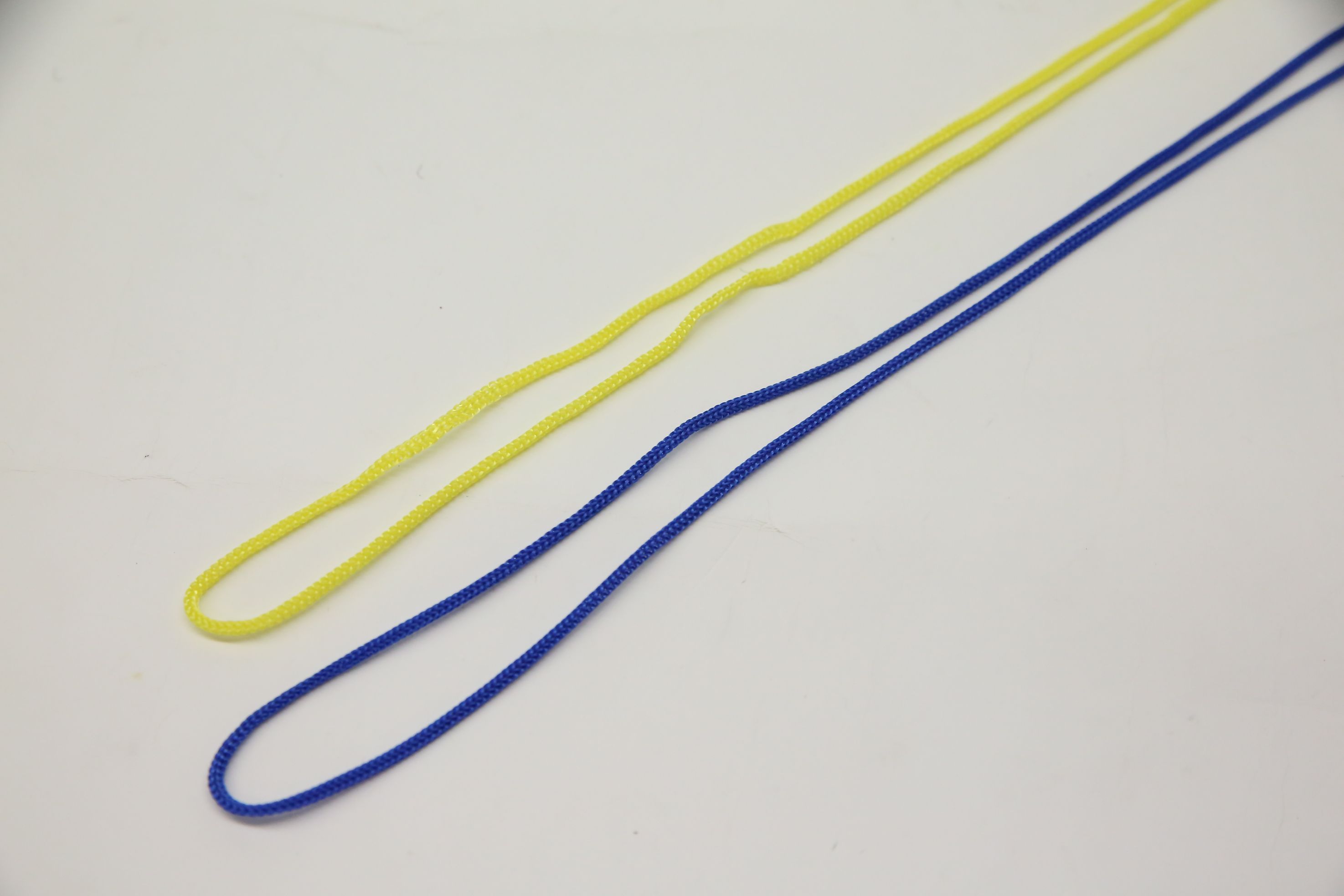

Compared to traditional cotton ropes, which absorb water and weaken when wet, or nylon lines that degrade under prolonged sun exposure, polypropylene shines. It floats, resists mildew, and withstands UV radiation—making it ideal for both indoor artistry and all-weather utility. And at just 2mm in diameter, it's light enough to coil tightly yet robust enough to handle serious load.

From Factory Floor to Your Fingertips: The Power of Direct Supply

We cut out the middlemen—not to save costs, but to guarantee quality. Every batch starts with rigorously tested raw pellets, extruded into uniform filaments using computer-controlled spinning systems. Each spool undergoes dynamic tension testing, ensuring no weak spots or inconsistencies. Because we control production from start to finish, you get the same reliable texture and tensile strength every time—no surprises.

Buying factory-direct doesn’t just mean lower prices; it means transparency. You’re not paying for branding markups or distribution layers. Instead, you’re investing in consistency, traceability, and value—all while supporting ethical manufacturing practices.

Three Ways to Unlock Its Hidden Potential

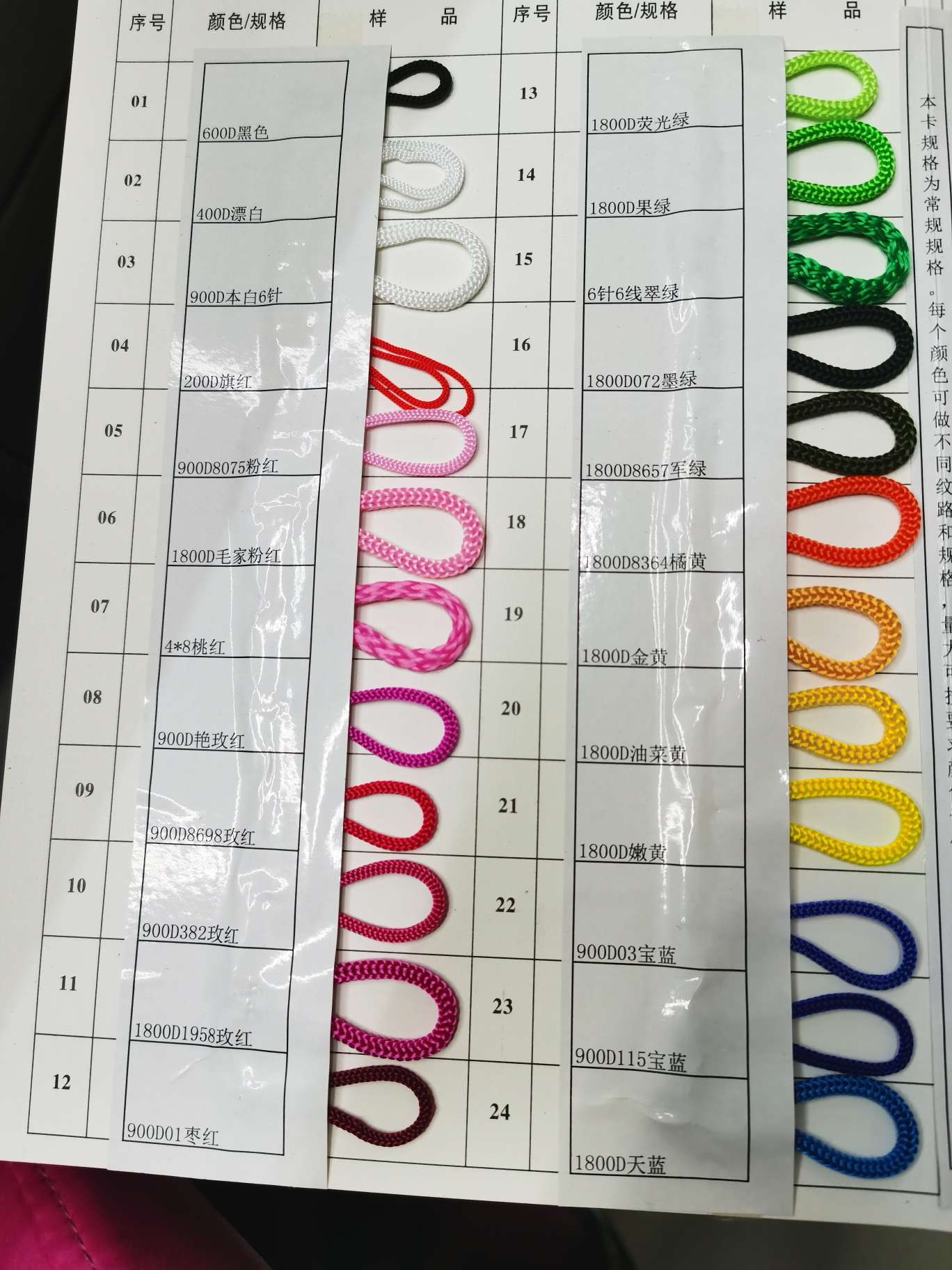

For Craft Enthusiasts: With its soft-hand feel and slight sheen, this rope glides effortlessly through crochet hooks and weaving needles. Try crafting textured coasters, pet-safe toys, or even large-scale macramé installations. Its minimal stretch ensures shapes hold over time, while its colorfastness keeps hues bright wash after wash.

For Outdoor Adventurers: Trust it when conditions turn harsh. Use it as a ridge line for tarps, guyline for tents, or emergency tow strap. Thanks to its waterproof nature, it won’t rot in damp forests or crack in freezing temperatures. Plus, its bright color options enhance visibility in low-light environments.

For Bag Makers & Designers: Reinforce tote handles, weave durable shopping baskets, or customize shoulder straps with ergonomic padding. The rope maintains structural integrity even with daily wear, resisting abrasion from pavement and friction from heavy loads.

Real Stories, Real Strength

Sophie, a fiber artist from Portland, used hundreds of feet of this rope to construct an immersive ceiling installation for a local gallery. “I needed something that wouldn’t sag,” she says, “and could hold intricate knots for months. The 400D held every twist perfectly.”

Meanwhile, Jake, an avid hiker in Colorado, credits the rope with helping him survive an unexpected downpour. “My tent poles snapped, but I rigged a full shelter using just paracord and this polypropylene line. It didn’t slip, stretch, or break—even soaked for hours.”

Choosing Right Is Risk Management

A failed knot can unravel more than a project—it can compromise safety. Low-grade ropes often suffer from uneven braiding, poor knot retention, or rapid fading. Our 400D rope exceeds standards in three key areas: uniform strand alignment (prevents fraying), high knot efficiency (retains >80% of linear strength), and superior dye penetration (no bleeding, even after repeated use).

Get Started: Tips for Beginners and Pros

New to working with synthetic cords? Start with basic knots like the bowline or taut-line hitch—they grip well without slipping. To prevent splaying, lightly melt the cut ends with a lighter. Want to add color? While polypropylene is hard to dye conventionally, fabric markers or heat-set pigments offer vibrant customization.

Advanced users can experiment by combining multiple strands for thicker weaves, or embedding the rope into resin-based composites for sculptural pieces. Think beyond binding—think building.

The Future of Rope: Beyond Utility Into Innovation

Polypropylene isn’t just durable—it’s increasingly sustainable. Recyclable through industrial processes and energy-efficient to produce, it aligns with eco-conscious design trends. Imagine urban planters suspended by colored ropes, kids learning knot-tying in STEAM classrooms, or modular fashion accessories made entirely from repurposed cordage. The possibilities are expanding—one strand at a time.

The 400D polypropylene rope may seem humble, but in the hands of creators and explorers, it becomes something greater. Stronger than cotton, smarter than nylon, and built for real life—it’s not just a supply. It’s a foundation.