In recent years, with the rise of handmade products and customized products, people have higher and higher requirements for woven materials. In particular, in terms of strength, wear resistance and diversified use of excellent performance of the product is highly respected. Today we will discuss why 400D polypropylene rope has become the first choice in many industries.

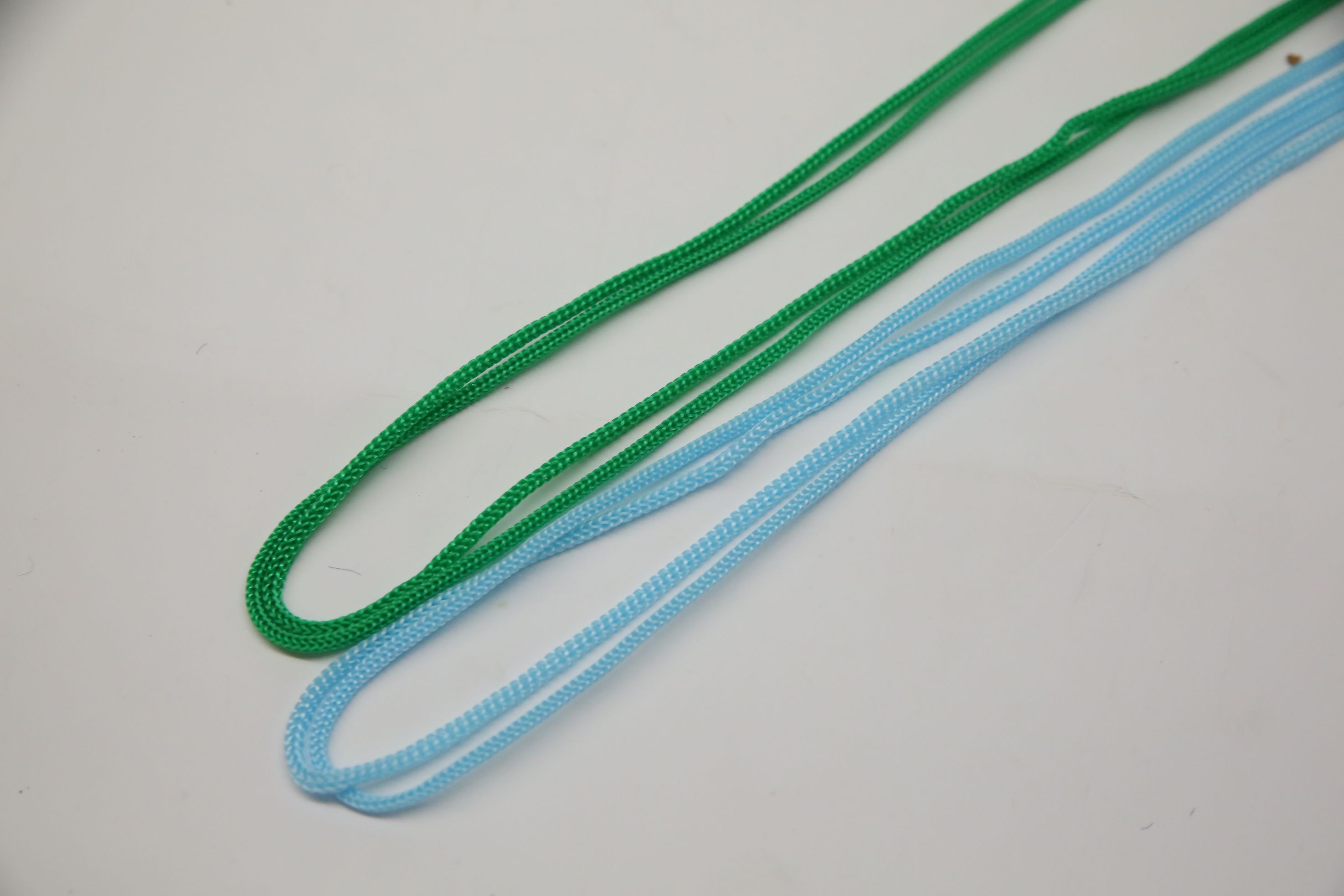

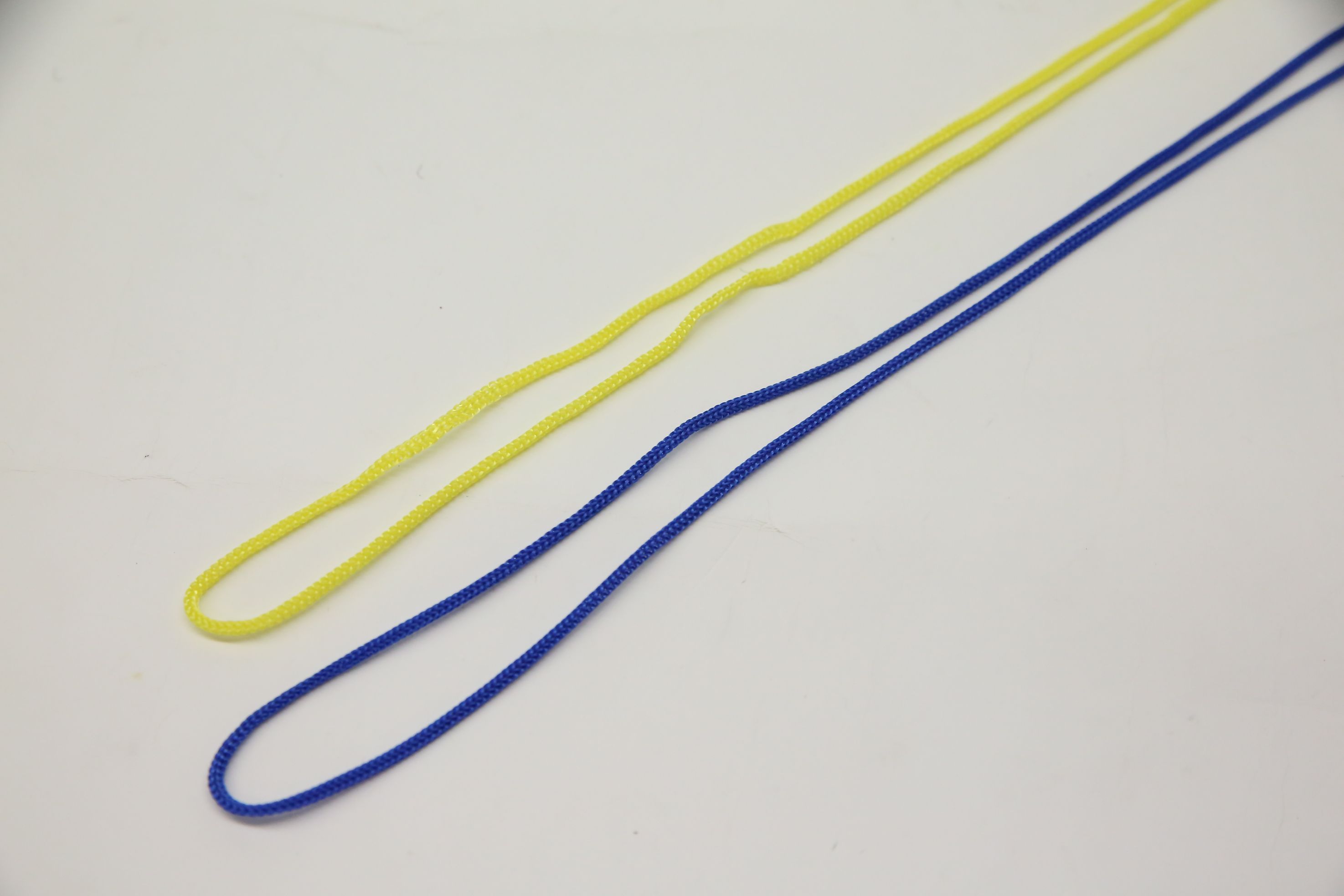

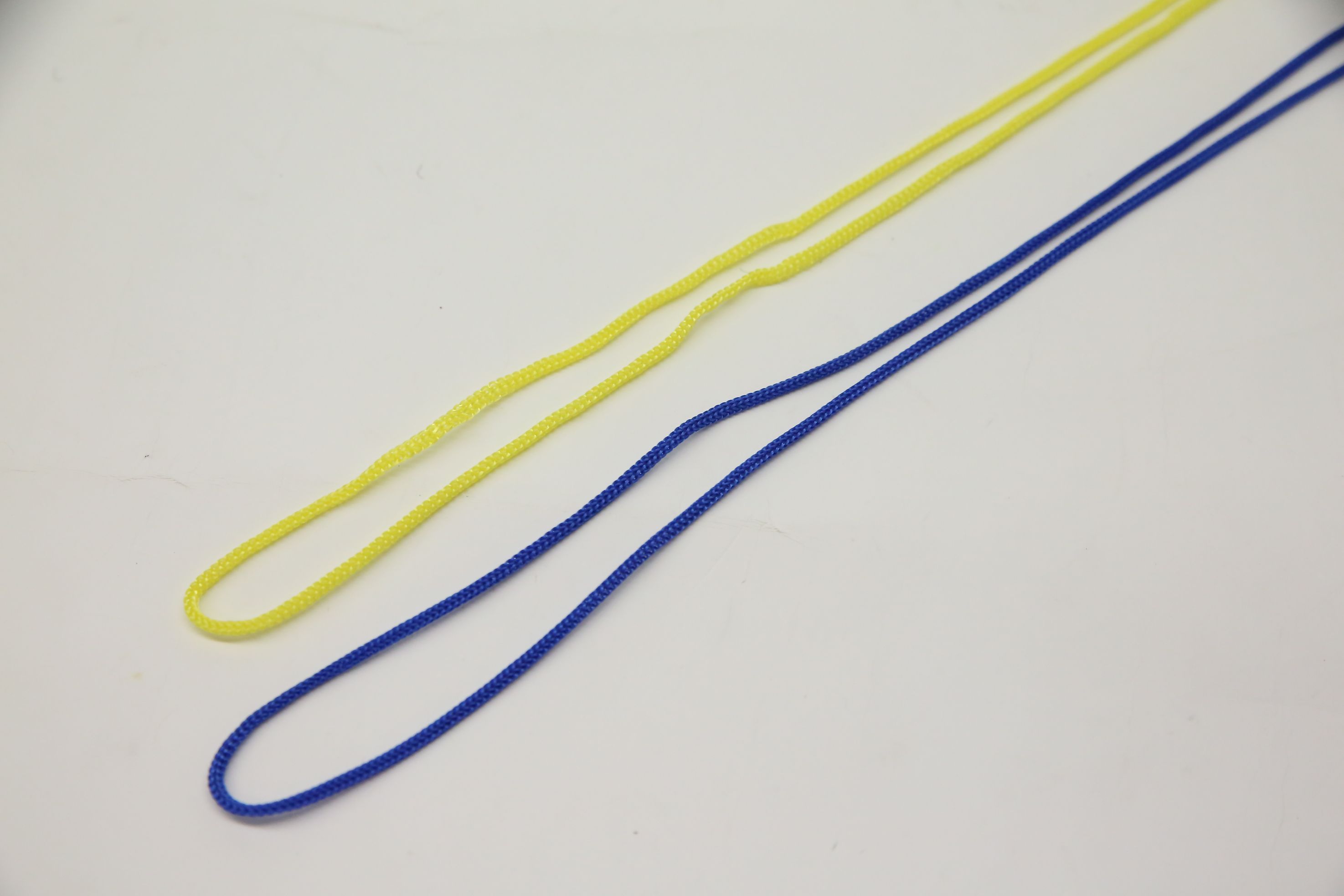

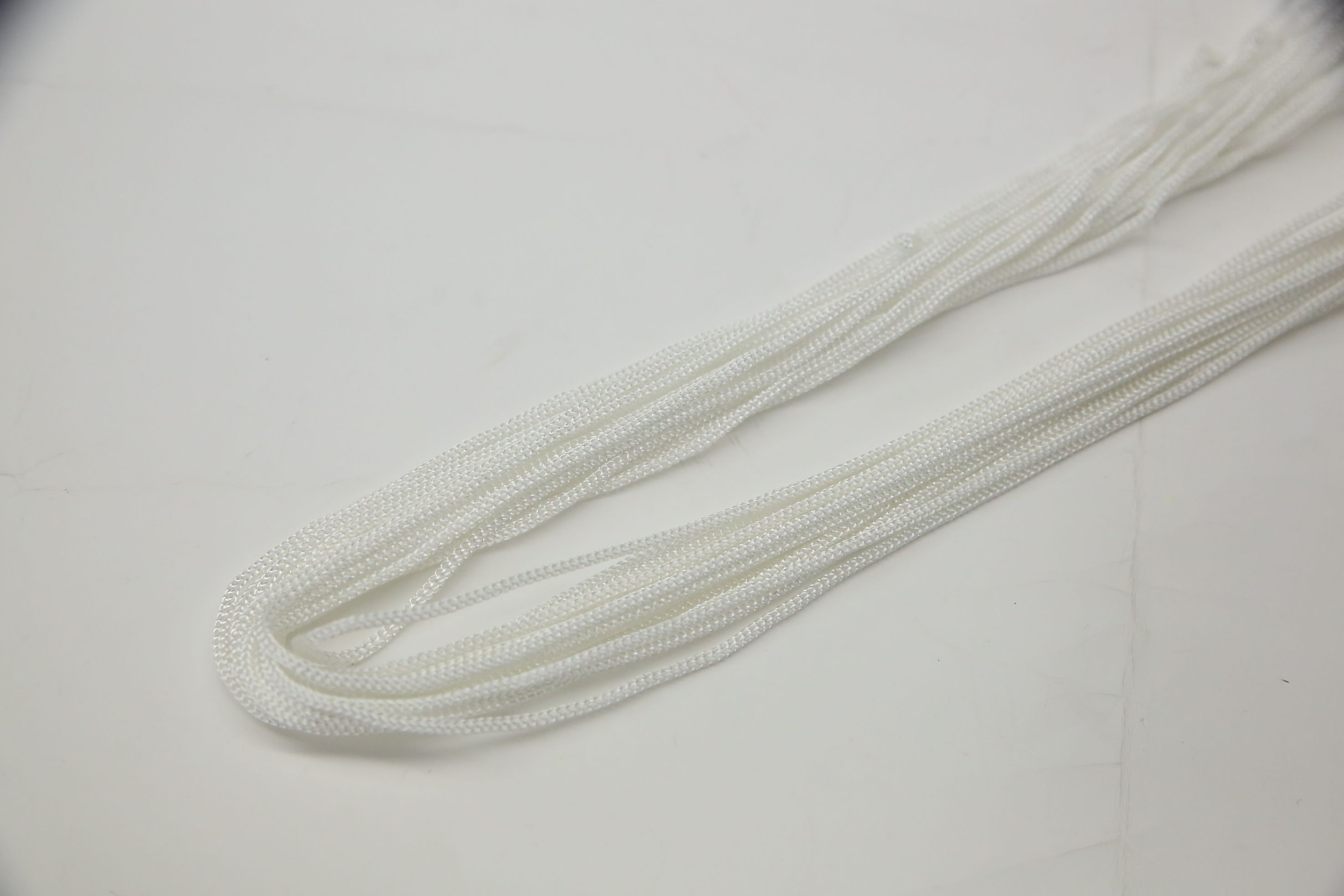

The first thing I have to say is its unique advantage-this material is made of high-density fibers, which not only ensures light weight, but also has extremely high tensile strength. Not only that, its smooth surface is not easy to knot and waterproof and moisture-proof properties also make it in outdoor activities or long-term storage environment is still in good condition. In addition, according to different customer needs to adjust the thickness and size specifications (such as 2mm provided in this paragraph), so that the application field more widely covers clothing accessories hook cord belt and even packaging reinforcement and other directions.

Next, let's take a look at how such an excellent quality is produced? From the selection of raw materials to the final molding factory, every step requires strict quality control to ensure that the final delivery to consumers are qualified products after precise calculation and repeated testing.

However, the variety of goods on the market is dazzling. How to make wise choices has become one of the key issues. In view of this, we can give a few simple and effective suggestions to help you find the most suitable option for yourself:

- -Make clear the priority of your needs, such as whether to pay attention to flexibility or to be more resistant to tearing;

- -judge which special treatment processes are more important to you in combination with the actual use environment, such as ultraviolet protective coating and other additional value addition;

- -Finally, don't forget to personally touch and feel the physical sample to confirm whether the handle texture meets the expected standard!

of course, in addition to theoretical knowledge, the evaluation of real users is often more touching. let's share some examples and stories of successful application of this product, hoping to inspire more inspiration and spark collision to come up with your own unique design scheme ~

Last but not least, there are some tips to teach you about how to better maintain and extend service life. Try to avoid long-term exposure to strong sunlight to prevent aging and embrittlement. It is better to store it in a dry and ventilated place when it is not in use at ordinary times to reduce the risk of external moisture erosion. Regularly check whether there are signs of loosening at the connecting parts at both ends and repair them in time to avoid greater losses.